Making the Bosch (and Wehrle) Metal Can Electronic

Voltage Regulators Adjustable.

>>A HOW-TO article<<

© Copyright 2021, R. Fleischer

http://bmwmotorcycletech.info/boschelreg.htm

22

I wrote this article because a few people asked for it. You can purchase an adjustable voltage regulator quite reasonably from http://www.RockyPointCycle.com or http://euromotoelectrics.com. But, the stock metal can regulators are not difficult to modify, the cost is very low, and you get to keep the original stock appearance …if you want-to. The metal-can VR’s are very reliable ….and are relatively easy to repair. They can even be modified to work with very high powered alternators for the Airheads (by changing the power transistor inside). These metal can regulators, no matter the name on them, MIGHT have been made by Bosch or Wehrle.

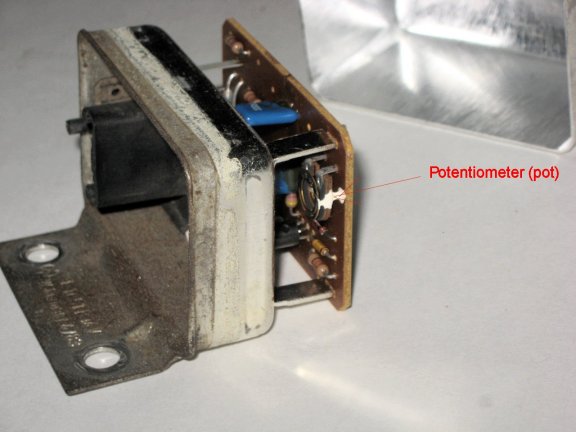

The exact same procedure is involved….(and the same hole drilling and adding a grommet, if you want to). Here is a photo of the Wehrle METAL CAN Electronic Regulator, with the potentiometer, with factory sealing paint. This is a how-to article, the purpose is to make your Bosch or Wehrle ELECTRONIC metal can unit easily adjustable. This article is NOT for the similar (but taller) metal can mechanical Bosch regulator…see https://bmwmotorcycletech.info/boschmechreg.htm.

In the photo just below you can see the potentiometer (a fancy word for an adjustable resistor) with the original factory sealing paint.

Also found on the Snowbum website is an article on increasing the voltage output of the plastic cased Wehrle.

https://bmwmotorcycletech.info/Wehrle.htm

The below information applies to BMW Airhead Motorcycles, but is also applicable to any other vehicle that uses these metal can electronic voltage regulators.

There are several ways to increase the voltage, which is the usual desire, including adding a tiny diode to ‘fool’ the regulator, but the method described below makes it fully adjustable. Don’t attempt this if you can’t work on small parts and use a small soldering iron comfortably. You MAY not need the soldering iron. You do not have to drill the hole in the cover, but that makes the regulator MUCH easier to adjust.

Parts needed (maybe):

1. One rubber grommet….no special size, from Radio Shack or autoparts store or? One using a 3/8″ mounting hole is fine, so is one of 1/4″ or 5/16″. The 3/8″ or even a 1/2″ might be better if you are not good at making measurements on where to drill….so read this procedure through. You don’t HAVE TO have a grommet, but you probably will want it. You will also want a common black plastic body plug that fits the center of the grommet hole…or, you could use tape. A plug is much nicer. When the adjustment is all done, use a tiny bit of RTV cement is to seal the plug so it stays in place. Read this entire article first, to decide if you will drill and get a grommet …or not.

2. A few Q-tips and some acetone, MEK, or similar strong solvent.

3. Small jewelers-type screwdriver.

4. Drill bits.

5. 100 ohm potentiometer (in case you ruin the existing one); then you’ll also need a small soldering iron and a inch or two of 60/40 electronics solder. A potentiometer is a small variable resistor used in electronics, & if you need one, it would need to mechanically & electrically fit the existing regulator, many common types fit just fine, some with minor work. If you are careful, you will NOT need this part ….and in any event, Radio Shack or most any local electronics shop should have them.

The electronic metal can voltage regulator consists of a number of transistors, diodes, resistors & capacitors, the purpose of which are not important to this article.

The Modification:

1. Remove the regulator from the bike. There are two allen head screws, and a plug to disconnect. You don’t have to remove or disconnect any battery connections.

2. Remove the tape from the regulator that keeps the top can from coming off.

3. Gently wiggle the top can off the base, these can be on tight, so work slowly.

4. Inside you will find a printed circuit board with all the components mounted upside down…that is, underneath the board. On the end of the board OPPOSITE the plug/socket end, you will find a small electrical device called a pot (short for potentiometer). This is the factory adjustment control. Every one I have seen is always sealed with a drop of a hard-to-remove white paint.

5. Try to remove or at least release the paint drop with repeated use of a WOOD-TUBE type Q-tip (some Q-tips use plastic tubing or plastic rod, that will dissolve in a solvent!) or a large common wooden toothpick, in something like acetone, MEK, or paint-remover-gel. Clean off any gel, if you used that. This can take some time. If you are successful, the pot will be usable as is, and then can be adjusted. If you are not successful, you can THEN, still wet from the solvent/gel, try VERY GENTLY prying a tiny bit at the paint, to free up the lower adjustment fingers metal ring. Do NOT pry much. I use a dental pick tool or very tiny screwdriver. As a last try before replacement, I have found it best to CAREFULLY unsolder the three legs of the pot and remove it, & soak it in acetone for a short while….which ALSO gives me SAFE access to ENLARGE the very tiny board hole for the adjustment (that is standard on the board). If you are VERY careful you could leave the pot in place & drill out that hole by hand …just don’t ruin the pot. You don’t HAVE to drill the tiny hole larger, but you will then need a VERY TINY jewelers screwdriver for the adjustment,….so I DO recommend drilling the board hole larger. What size? Whatever you wish, to match your jeweler’s screwdriver (or a modified nail) that FITS THE POT SLOT. If you ruin the pot, it will have to be replaced, with any common 100 ohm pot that fits, or can be made to fit. Try to be very careful, & not ruin the existing part.

6. Assuming the pot is operational, or the replacement is installed; as noted above, you can enlarge the the circuit board existing hole for access by a larger sized jewelers screwdriver. If you intend to make the regulator adjustable from outside the can, then you have an optional step now. That is to drill the thin metal cover in the appropriate place, and install a rubber grommet. The purpose of the rubber grommet is to keep you from electrically shorting the potentiometer metal to the regulator cover metal when adjusting the voltage regulator with a metal-shank screwdriver.

You don’t have to have the hole in the top of the can & grommet. You can set the regulator without the cover on. The cover, whether on or off, has NO magnetic effect on the adjustment, so you CAN install the VR, make the adjustment with a very tiny jewelers screwdriver (cover off), and then simply replace the cover, using sealing tape. This completely negates any need for drilling or a grommet. It is your choice. You can always add the hole and grommet later, if you want to.

I DO recommend drilling the potentiometer hole in the board hole larger. You do not have-to.

You WILL find the can hole convenient, but NOT absolutely necessary for future adjustments …such as if you change the battery to a type needing a different voltage, ETC.

The standard 13.8 volts as VR’s typically come from BMW, is TOO LOW for modern batteries; and, I think it too low for the original flooded batteries, particularly in stop and go city traffic. If you use the hole & grommet, it’s nice to seal it’s hole with something. I use a common black plastic auto-body plug, that fits into the center hole, and I use a wee dab of silicon rubber …that stuff in a squeeze tube to keep that plug in place. Easy to remove & readjust whenever you might like to, and the regulator remains relatively weatherproof.

DO NOT mix up the information on the holes. You do NOT ‘have to’ drill either hole. READ the information!

7. Be sure all is assembled correctly. Re-check your work. Install the grommeted cover (if so done); be sure your jeweler’s screwdriver will fit the pot slot rotate the pot back and forth a wee bit. If you are worried about the pot being OK, you could use an ohmmeter to prove that the pot is about 100 ohms between the ends, & that the wiper, with respect to either end, works properly on the ohmmeter as you turn the pot, before re-installing the metal cover.

8. Reinstall the stock factory cover tape at the junction of cover & base; install the regulator on your bike & plug it in. If you are not drilling the hole and installing the grommet, leave the cover off and adjust the VR, then replace the cover and tape.

9. Adjustment of the regulator is done by using the jeweler’s screwdriver, making SURE the metal of the jeweler’s screwdriver can NOT contact the metal can if drilled, …there MUST be a grommet installed. The screwdriver MUST be the right size, or you will ruin the pot. Be gentle in downward pressure when trying to engage the pot. The screwdriver works by fitting into a slot in the pot, to rotate the pot contact fingers.

10. The voltage setting depends on your usage of the bike, the type of battery, & the temperature of the regulator when making the adjustment. The regulator is, or should be, temperature compensated & is DESIGNED to INcrease its voltage very slightly as the temperature of THE REGULATOR goes down.

Some guidelines:

I will assume here the engine will be started & regulator adjusted within a FEW minutes (so the regulator has NOT warmed up from engine heat). The GOOD battery, load test if unsure, is fully charged to begin with. Just because your battery SEEMS good does NOT mean it is good enough for a VR adjustment …so charge the battery fully, let it sit 2 hours, and then do a formal Load Test, using a load tester, perhaps from Harbor Freight Company (their 2-meters version is quite decent).

Do not do any adjusting unless your alternator brushes are good, your battery connections good, and your battery load-tested good.

Voltage must be set AT THE BATTERY TERMINALS, using a digital voltmeter. Start the bike. With only the starting-up battery drain (with headlight and running light is OK), ….the engine is slowly raised to perhaps 3500-4000 RPM. The battery will be quickly recharged to whatever the pot setting happened to be at. Adjust the pot for approximately 14.1 volts. The final adjustment is done when you are SURE the battery is recharged, and do it in accordance with the information that follows:

For common flooded batteries, a good compromise between water usage and charging is 14.1 for 70°F as measured on the VR metal case. For other temperatures:

For 47°F 14.4 volts

For 70°F 14.1

For 93°F 14.0

For 117°F 13.9

For somewhat better battery life, & faster recharging, add 0.2 to those voltages. For short stop & go commuters (such as inner cities), I especially recommend that additional voltage. For sealed/AGM/VRLA batteries, I recommend 0.3 volt additional instead of 0.2 volt.

SOME types of sealed batteries can use, successfully, 14.5 to 14.9 volts at 70°F. Check your battery maker’s specifications. I would not use over 14.5 for long distance touring.

All voltage readings are taken AT the BATTERY terminals themselves!!, and NOT from your fairing voltmeter!!! You must have an accurate digital voltmeter. Your battery connections to the bike’s system must be clean, solid, etc. If you have corrosion or connection problems ANYplace in the system, or even a wonky ignition switch, voltage regulation may be poor. Suspect places are the battery terminals, battery wires (especially internally of the insulation within 2 inches of the + terminal), the starter relay plug & wiring there, the ignition switch, the large red wire that plugs into the diode board on the right side as you face the board from the front of the bike, and do check the tightness of these connections including the alternator phase wire plugs.

Problems with VR & output will also come from poor grounding of the diode board. If you have rubber mounts, get rid of them & install aftermarket metal mounts and correct grounding wires BEFORE you do any VR adjusting. Article is on the Snowbum website: https://bmwmotorcycletech.info/diodebds&grdgwires.htm

NERDY:

Interested in what ONE VERSION of an electronic VR schematic looks like?

https://bmwmotorcycletech.info/VRschematic.htm

Want to adjust the VR on the workbench?

I suggest you don’t try to do the bench test information in this section, unless you are the nerdy technical type with an adjustable power supply, ETC, and ‘just want to do it’. Elsewhere’s on the website is generic information on measuring the ‘set point’ of regulators. https://bmwmotorcycletech.info/testingvoltageregulators.htm. You do NOT have to go though that procedure!

Bench Test method for those having an adjustable power source, and wanting a ‘bench’ test:

Keep in mind that this is NOT a test ON the bike, but with the regulator on your workbench ….seems self-evident, but I have had some confused readers!

I use an old 55 or 60 watt headlight lamp as a load, but almost any lamp or 5 to 20 ohm power-type of resistor will work (power resistor of 10 watt rating is OK for short term testing).

It is FAR easier to use the lamp!

Before you start: you should connect things with the power source turned OFF; recheck the connections several times BEFORE turning on the power source. DO NOT connect anything wrongly!

The purpose of the headlight is to simulate the ROTOR resistance which it does quite well, & as an indicator for the procedure! It really works well.

Connect one side of the headlight lamp to the terminal marked DF; the other side of the lamp to the power source negative(-).

Connect the D+ terminal to the power source positive (+).

Connect the power source negative to the D- terminal.

Connect the digital voltmeter + red test prod to D+ .

Connect the digital voltmeter – black test prod to D-.

Raise the voltage slowly. As the voltage rises, the lamp will start lighting up. Continue to raise the voltage but now do it very slowly. The lamp will suddenly go OUT. Repeat this, restarting at near zero on the power source, this time watch the voltage AS CLOSELY as you can JUST BEFORE THE LAMP GOES SUDDENLY OUT.

Retry SEVERAL times, lowering the voltage & start raising it again, slowly. You must be careful & accurate as possible. Your adjustable supply may increase in voltage when the lamp goes out, so try to read the exact voltage when the lamp is as close as possible to going out, but hasn’t, yet. Adjust the pot to where you want the voltage (the exact point before the lamp goes out), install the regulator into the motorcycle as noted, and make a small final adjustment if you have to (likely). Keep in mind the guidelines & temperatures. Your battery MUST be in good condition and fully charged to begin with, as you want the system to not be using excess electricity to charge the battery….you are after what is called the ‘float voltage’….and the electrical connections having to do ANYthing with the alternator MUST be good and proper!!!!

Revisions:

06/14/2017: Copy to Airheads.org, update/edit.

02/13/2021: Emphasis and clarifications, mild.

© Copyright 2021, R. Fleischer